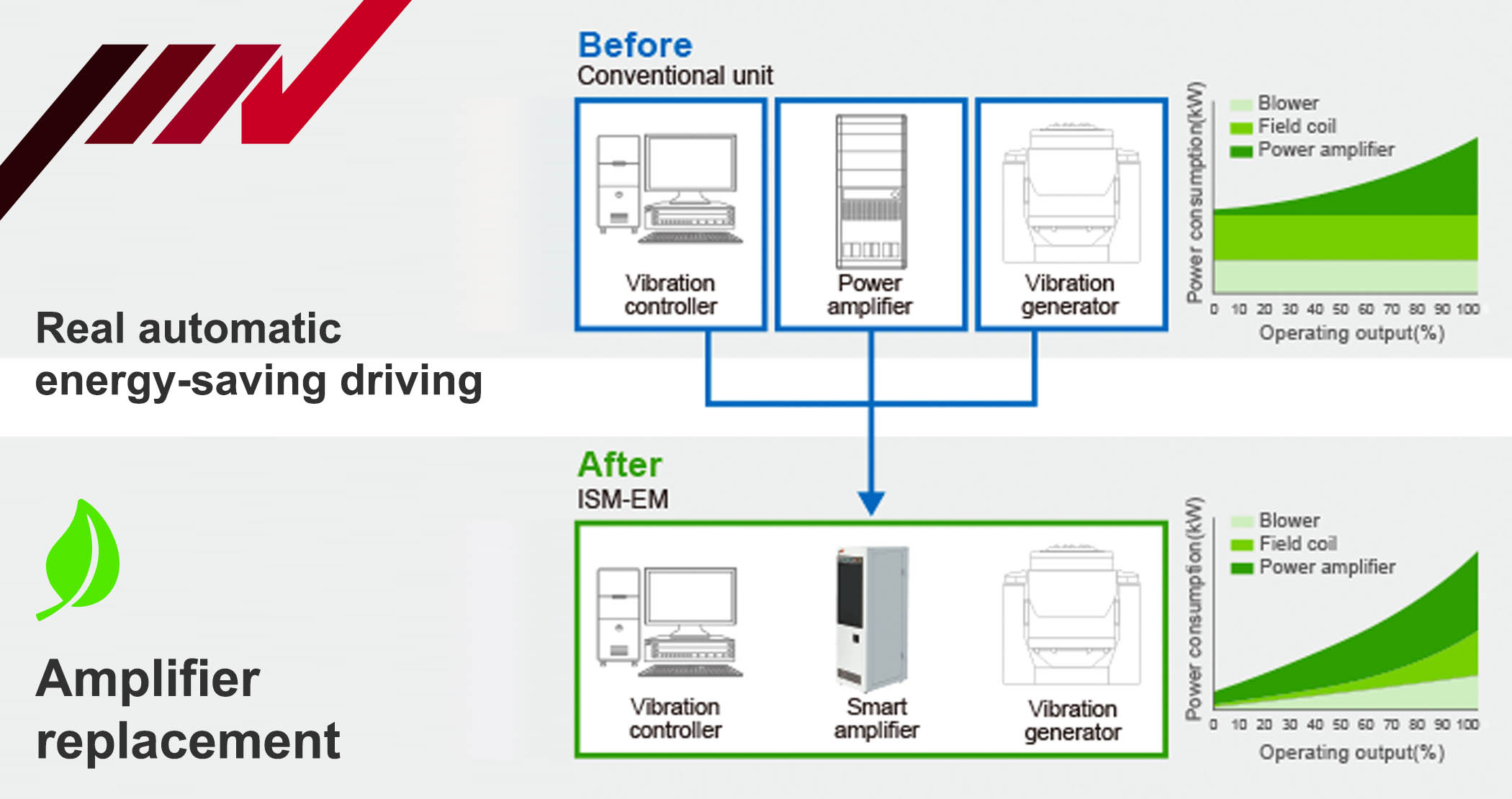

Amplifier replacement

IMV has developed super-long life amplifiers with Integrated Shaker Manager technology which; minimizes the required electric power, cuts down electric consumption, reduce blower noise if air-cooled type shakers and have significant reliability.

ISM-EM can be adapted even to existing vibration shakers by any manufacturer apart from IMV. All you need to do is renewing the amplifier and add software in the computer of the existing vibration controller.

Real automatic energy-saving driving

Complicated settings are not necessary.

Lower your noise emissions

Reduce your carbon footprint.

Result of reduced power consumption

When it's 20% output : 70% reduction.

When it's 40% output : 40% reduction.

The reduction effect noted above is just an example, so it could be different depending on the updated system.

BENEFIT

Saving running cost

Conventional shaker systems set the field power and blower speed to the nominal settings as soon as the system is started. Only the armature power is varied according to the force required for the test.

IMV’s ISM-EM technology constantly monitors the force required to operate the vibration test and by using the high frequency power converters, and automatically adjusts the field power and cooling blower speed to run at the point of minimum energy consumption.

Increase durability

IMV shakers’ durability is already well known in Japan, Asian countries, Russia, and Europe. We have installed about 200 multi-axis systems in the world for these 20 years in addition to a large number of single-axis shaker systems. In the United States, we have one of the testimonials in the automotive industry test house, Spectrum Technologies, Inc., located in Redford, MI. It has two of simultaneous 3-axis shaker systems (TS-2000-6H : 4,400 pound-force each axis). The first system was installed about 10 years ago and the second one was installed in November 2017. Both shaker systems are mainly used up to 2,000Hz for one of the “Big Three” automakers’ components durability tests. The first shaker system shows IMV’s real-world durability with no down time until now. As of November 2016, its hour meter on the amplifier shows “23,213 hours” (refer to the picture below) without any maintenance for about 10 years. In fact, our claimed amplifier MTBF is 17,537 hours, and thus the amplifier at Spectrum Technologies, Inc. successfully proved our advanced durability of 4th generation IGBT amplifier. Please note that IMV amplifiers can operate under ambient temperature of 104 Fahrenheit (40°C).

Noise reduction (for air-cooled type) = Quiet shaker

In minimizing the energy used by IMV’s ISM-EM to run any particular test, then the cooling requirement is also minimized. Not only does this save energy, but it also means that for most tests, the ISM-EM is quiet. Air-cooled shaker systems are sometimes criticized for the level of blower noise, but IMV’s ISM-EM solves this problem. For low force tests, the cooling blower automatically runs at a reduced speed and the total system noise level is much reduced. When the shaker is running at full force, the noise from the shaker table exceeds that of the blower and the blower noise is not an issue. Many of IMV’s customers are buying the ECO-system for the noise reduction alone and the energy saving is an additional benefit. The figures below show the measured sound levels of IMV’s i260 shaker of the rated force 54 kN (12,100 lbf) when operating in the ECO-power saving mode.

Advanced service support / (Remote) Maintenance manager

IMV’s ISM-EM monitors up to 200 parameters, including for example power module operating conditions, system temperatures, interlock status, controller status, 3-phase supply conditions and so on. By recording these parameters and saving them to a log file enables advanced diagnostics to be made on the system. Further, each time a system interlock occurs, a snapshot is taken of the system operating parameters both before and after the interlock occurred.

All of this information means that IMV can remotely diagnose a system problem such that:

- The problem can be resolved remotely and the system is back up and running without the need for service engineer to visit

- If a service visit is required, the engineer will bring the correct spare part and have the system running again in only one trip.

Everything is done to keep the ISM-EM running for the maximum amount of time and maximize your return on investment.

ECO TECHNOLOGY

All advantages at a glance

- Reduction of field power to less than 50% without noise at the shaker armature

- Ideal operating point; Automatic adjustment of level for field and armature

- Automatic adjustment during test execution

- Optimization without user knowledge of the technology

- The optimization is performed automatically based on the actual parameters of the test

- Automatic switch-off at the end of the test

- Provides diagnostic options in case of error

- Optimization based on performance data

- Field power can be adjusted manually or automatically for increased shock velocity

- Integrated operation of the amplifier from the vibration controller

- Can also be retrofitted for older shaker models from all manufacturers